How an Industrial Coffee Grinder Improves Brew Consistency

How an Industrial Coffee Grinder Improves Brew Consistency

Blog Article

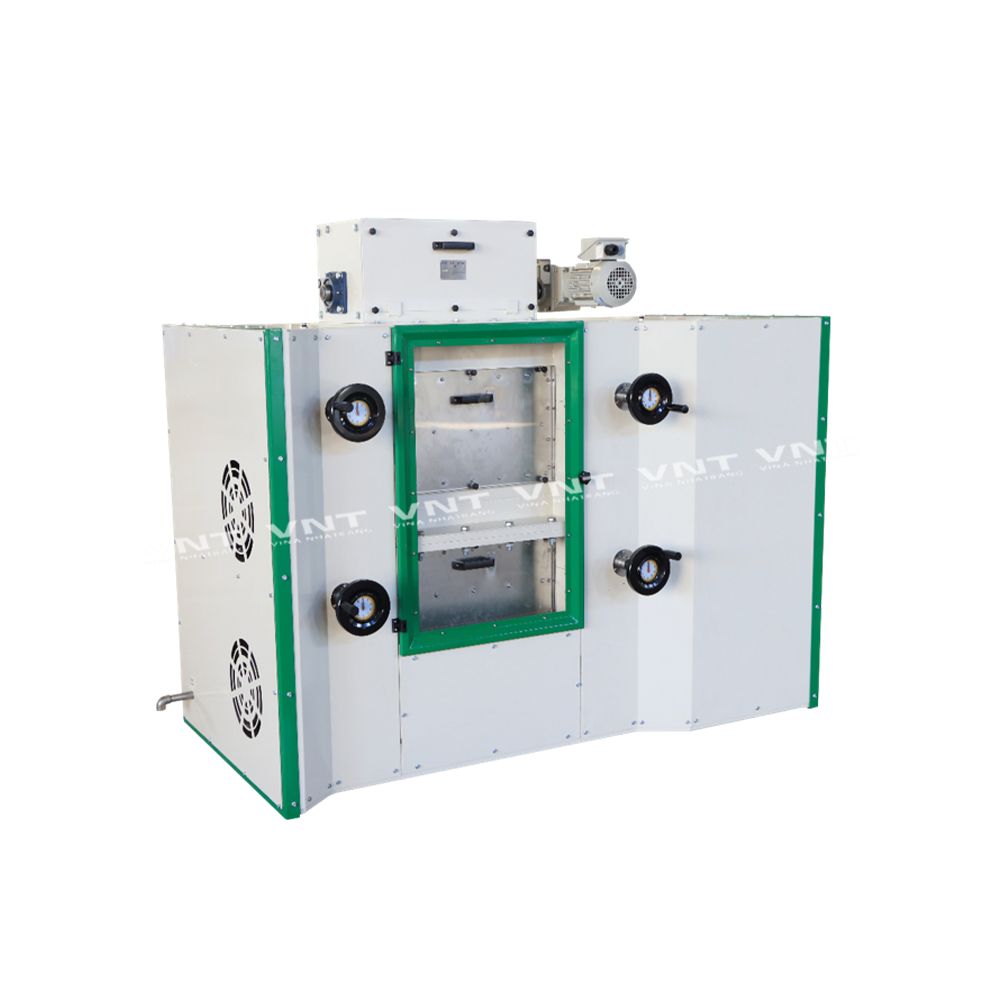

Industrial Coffee Mill Guide: Boost Performance and Quality

In the competitive landscape of coffee production, picking the appropriate industrial coffee grinder plays a pivotal duty in boosting both performance and item quality. Understanding the nuances of various grinder types and crucial functions-- such as personalized grind settings and robust building-- can dramatically affect the last flavor account of the coffee.

Comprehending Grinder Types

When picking an industrial coffee mill, comprehending the various types available is important for enhancing both taste extraction and functional effectiveness. The 2 key types of grinders are blade mills and burr grinders.

Ultimately, picking the right kind of grinder is essential to preserving quality and efficiency in coffee production, making it essential for services to invest in high-grade burr mills for optimal results.

Secret Attributes to Think About

Choosing an industrial coffee grinder needs mindful factor to consider of numerous vital attributes that can substantially affect both performance and the total coffee experience. Among the key aspects to assess is the grinding mechanism. Burr mills are generally favored over blade mills, as they give a regular work dimension, which is crucial for optimum extraction and taste.

Another important attribute is the mill's capability. A flexible mill with numerous settings allows you to customize the work size to different brewing approaches, improving the coffee's taste account.

The building product likewise plays a function in longevity and upkeep. Stainless steel components typically supply long life and are easier to clean, which is vital for maintaining health requirements. Last but not least, review the mill's noise level, particularly in a busy coffee shop or manufacturing setting, where extreme noise can be turbulent. Investing in a grinder that balances these functions can significantly enhance both operational effectiveness and the high quality of the coffee served.

Optimizing Grinding Process

To accomplish the finest outcomes in coffee prep work, enhancing the grinding process is vital. The work size considerably affects extraction, taste, and total quality of the made coffee.

In addition, keeping track of the grinding speed can maximize the procedure. Slower grinding typically creates much less warm, maintaining fragile flavors and scents. Conversely, quicker grinding may produce excessive warm, adversely affecting the coffee's high quality.

Upkeep and Care Tips

Appropriate maintenance and treatment of industrial coffee grinders are crucial for making sure ideal efficiency and long life. Normal cleaning is the structure of upkeep; residue buildup can influence taste and grinding performance. It is advisable to cleanse the mill after each use, cleaning down the exterior and getting rid of any type of coffee premises from the burrs.

Furthermore, inspect the grinding burrs for damage. Plain burrs can compromise grind consistency, so they must be replaced as needed. Industrial Coffee Grinder. Periodically calibrating the mill is also crucial, as this keeps the preferred work size for numerous brewing techniques

Lubrication of moving parts should be performed according to the maker's specifications, as this minimizes rubbing and prolongs the life of the tools. It is important to utilize click this site food-grade lubes to guarantee safety and security and conformity with wellness policies.

Lastly, maintain the grinder in a completely dry and secure setting to prevent rust and corrosion. By sticking to these maintenance and care tips, operators can improve the effectiveness of their industrial coffee grinders while ensuring high-quality outcome and expanded operational life.

Roi Evaluation

Assessing the roi (ROI) for commercial coffee mills is essential for businesses looking for to optimize their coffee production capabilities. An extensive ROI evaluation helps establish the monetary stability of investing in premium mills, allowing organizations to consider the preliminary prices against prospective gains.

To carry out a detailed ROI analysis, businesses must consider numerous essential elements. First, analyze the purchase cost of the mill, consisting of installment and any type of required adjustments to existing infrastructure. Next off, compute functional costs, consisting of energy consumption, maintenance costs, and labor performance enhancements. High-performance grinders commonly cause decreased grinding time and raised throughput, which can substantially enhance performance.

Additionally, think about the influence on item quality. Industrial Coffee Grinder. Superior grinders yield an even more consistent work size, which can improve flavor profiles and consumer contentment, inevitably driving sales. By increasing the quality of the end product, organizations can warrant greater rates, causing increased revenue

Verdict

In summary, an industrial coffee mill plays a pivotal role in improving both performance and item top quality within coffee manufacturing. Ultimately, the tactical financial investment in a reliable grinder contributes significantly to enhanced profits and competition in the coffee sector.

In the affordable landscape of coffee manufacturing, choosing the appropriate industrial coffee grinder plays a pivotal duty in improving both effectiveness and product quality. The 2 key types of grinders are blade mills and burr grinders. Within the burr mill classification, there are level burr grinders and cone-shaped burr mills, each with its advantages. Burr go to this web-site mills are normally liked over blade mills, as they provide a constant grind size, which is important for optimum extraction and flavor.

In summary, an industrial coffee mill plays a pivotal role in enhancing both efficiency and product top quality within coffee manufacturing.

Report this page